Gas-solid instrumentation development and industrial applications

An important prerequisite for conducting experiments in gas-solid systems is to develop instruments capable of recording the principal variables in these systems inline, most notably bulk density of powders and grains and their moisture content. In this context, we have designed new diagnostic techniques since 1985. Notably, we created dielectric inline measurements of solid volume fraction and moisture content for a variety of systems (industrial plants, snow pack, sand dunes, fluid beds) and refined optical fiber techniques.

A fruitful collaboration with Merck has led to the development of industrial instrumentation, such as the level sensor described in the article below, which allow feedback control in continuous pharmaceutical manufacturing.

Michel Y. Louge, Jasdeep Mandur, William Blincoe, Anthony Tantuccio, and Robert F. Meyer: “Non-invasive, continuous, quantitative detection of powder level and mass holdup in a metal feed tube,” Powder Technology 382, 467-477 (2021).

In this article, we describe a quantitative, non-invasive capacitance detector providing a rapid signal that varies continuously with powder level and/or mass holdup in the metal feed tube of a tablet press. We outline the principle of its processing electronics, provide an algorithm for the accurate interpretation of its signals, pose general design guidelines for embedding the instrument in the tube, and show how the detector can be paired with another non-invasive reference probe to operate with varying powder blend and moisture. We illustrate a control strategy that keeps powder level constant with a process example.

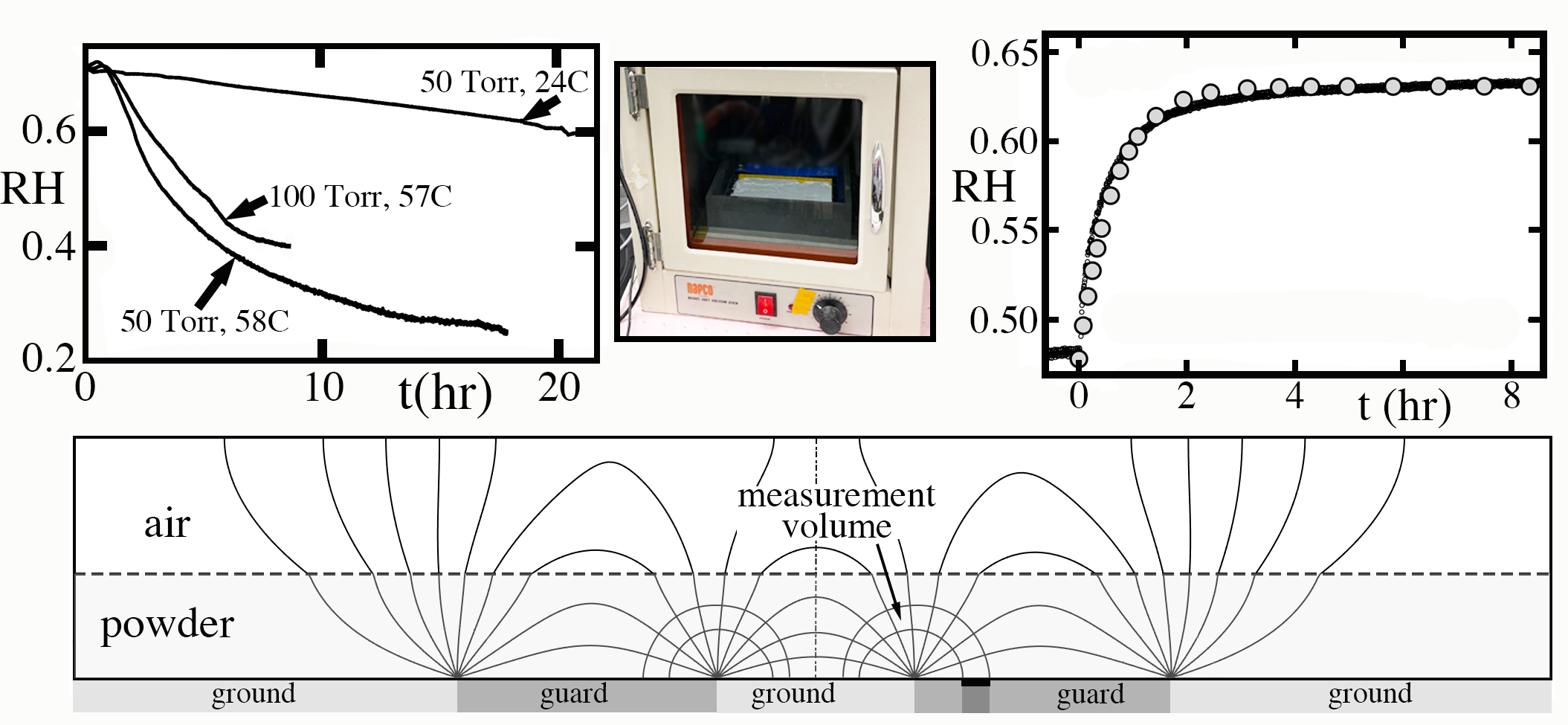

Another fruit of our collaboration with Merck is the "Smart Tray"

shown above, a device used in vacuum dryers to evaporate residual

solvents from spray-dried intermediate powders. The following article details how this is done. You can also download the Matlab programs IsothermalDryingST.m and SmartTrayFiniteDifference.m , which model, respectively, the drying process and the electric field in the Smart Tray.

Louge, M.Y., Mandur, J., Grigorov, P., Blincoe, W., Lamberto, D., Bower, C. and Meyer, R.F.: “Non-Invasive, Continuous, Quantitative Detection of Solvent Content in Vacuum Tray Drying,” The AAPS Journal 26(5), p.89 (2024).

A non-invasive capacitance instrument was embedded in the base of a vacuum-drying tray to monitor continuously the residual amount of solvent left in a pharmaceutical powder. Proof of concept was validated with Microcrystalline Cellulose laced with water, as well as water/acetone mixtures absorbed in a spray-dried Copovidone powder. To illustrate the role of impermeability of the base, we derive a model of vapor sorption that reveals the existence of a kinetic limit when solids are thinly spread, and a diffusion limit with greatly diminished effective diffusivity at large powder thickness. By monitoring the residual solvent content of powders, this new in situ technique offers advantages over indirect methods like mass spectrometry of vapor effluents, but without complications associated with probe fouling. To prescribe design guidelines and interpret signals, we model the electric field shed by the probe when a powder holds variable solvent mass fraction in the vertical direction.

The technique to record the moisture or solvent content in powders originated in our field research on snow packs and deserts.

Papers published on these subjects provide exhaustive details how our

unique technique works. Our work on the Smart Tray was covered in a news release of the Cornell Chronicle, and later articles such as this one from the National Tribune, this one from MirageNews and this one from Medicalxpress.

Earlier results and publications on instrumentation

For a earlier synoptic view of instrumentation in gas-solid flows, see Louge, M.: “Experimental Techniques,” ch. 9 in Circulating Fluidized Beds, J. Grace, T. Knowlton and A. Avidan, eds, Blackie Academic & Professional (1997), pp. 312-368.

Our other main publications on this subject include:

M. Louge, M. Tuccio, E. Lander and P. Connors: “Capacitance Measurements of the Volume Fraction and Velocity of Dielectric Solids Near a Grounded Wall,” Rev. Sci. Instrum. 67 (5), 1869-77 (1996).

In this paper, we describe a capacitance technique to measure solid

volume fractions in vessels, such as industrial fluid bed reactors,

where the wall is a metal held at a reference voltage. By

cross-correlating signals from two adjacent probes, we also use the

technique to record suspension velocity. This work is the object of US

patents 5459406

and 5546006,

which are licensed to Capacitec,

Inc.

An excerpt of Louge, et al (1996) is

available here.

A. Elizabeth Griffith, M.Y. Louge and Jamaludin Mohd. Yusof: “Simultaneous, Non-invasive Measurements of Convective Heat Transfer and Solid Volume Fraction at the Wall of an Entrained Gas-Solid Suspension,” Rev. Sci. Instrum. 71, 2922-2927 (2000).

In this paper, we describe a constant-temperature heat flux probe

fitted within the central grounded surface of a capacitance probe. This

allowed us to conduct simultaneous

measurements of solid volume fraction and heat transfer coefficient at

the wall of vessel holding a gas-solid suspension.

An excerpt of Griffith, Louge and Mohd.

Yusof (2000) is available here.

Louge, M.Y., Iyer, S.A., Giannelis, E.P., Lischer, D.J. and Chang, H.: “Optical Fiber Measurements of Particle Velocity using Laser-Induced-Phosphorescence,” Applied Optics 30, 1976-81 (1991).

In this paper, we demonstrate a method to measure the velocity of

phosphorescent tracers in a gas-solid suspension.

An excerpt of Louge, et al (1991) is available here.

Lischer, D.J. and Louge, M.: “Optical fiber measurements of particle concentration in dense suspensions: calibration and simulation,” Applied Optics 31, 5106-5113 (1992).

In this paper, we simulate the response of an optical fiber probe

measuring solid volume fractions in a fluid-solid suspension using a

Monte-Carlo technique launching photons at random consistent with fiber

characteristics and recording the fraction returning to the probe. We

also generalized this analysis to other kinds of optical fibers, see Louge (1994). These zipped

files contain the FORTRAN

simulation programs, which are thoroughly commented. Other zipped

files contain MS Word transparencies of a presentation on gas-solid

instrumentation, and another on optical

fiber measurements of solid volume fraction.

An excerpt of Lischer and Louge (1992) is

available here.

Louge M. and Opie M.: “Measurements of the Effective Dielectric Permittivity of Suspensions,” Powder Tech. 62, 85-94 (1990).

In this paper, we describe a technique to evaluate the effective

dielectric properties of a suspension of powders, and we review

homogenization theories and models.

An excerpt of Louge and Opie (1990) is available

here.

Acree Riley, C. and Louge, M.Y.: “Quantitative Capacitive Measurements of Voidage in Dense Gas-Solid Flows,” Particulate Science & Tech. 7 51:59 (1989).

In this paper, we outline the capacitance technique and its use in a fluid bed. Since this 1989 publication, we have applied the technique in circulating fluidized beds, a coal burning powerplant, snow packs and avalanches, and sand dunes; we have also coupled it to a small flux meter, and used it to calibrate optical fiber probes. We offer a short tutorial on the use of capacitance probe with pure dielectric solids.